Carving, grinding, screwing for the good sound

Apprentices from 135 professions presented their work at Swiss Skills in Bern from September 12 to 16. The various musical instrument making disciplines were also represented and attracted a large audience.

In Hall 1.1 on the Bernexpo site, the smallest professions from coopers to cable car mechatronics technicians are presented. And also musical instrument makers: in the area of workbenches and improvised showcases with organ pipes, bells and measuring instruments, apprentices are busy planing, gluing, drilling and tuning. They use mechanical piano and organ models to explain how the instruments work. Of the incalculable number of young people streaming past - over 115,000 people have visited Swiss Skills - quite a few stop to watch and ask questions. Who knows, maybe one or two of them will decide to take up one of the six professions that can be learned in Switzerland in musical instrument making in a four-year apprenticeship and graduate with a federal certificate of proficiency: Organ builder, organ pipe maker, piano maker, wind instrument maker, wind instrument repairer and violin maker.

-

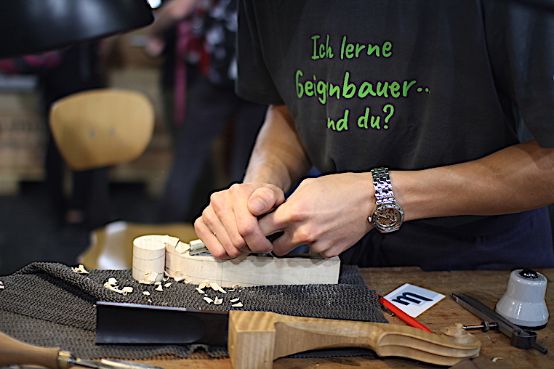

Elias Graf, a future 2nd-year violin maker, works on a violin scroll and explains why slow-grown sycamore maple is the best wood for it.

Training to become a violin maker - which involves making the entire string family up to the double bass - is organized as a training workshop at the Brienz Violin Making School. It offers both craft and vocational instruction on site and has just moved into a new building. "By building new instruments with a traditional touch, the young people can learn everything they will need later in their careers, including for service work," explains Hans Rudolf Hösli, head of the violin making school. "We have no worries about recruiting new talent. We can choose from among the applicants and have no problem placing the young people in the free market after their apprenticeship. Over the year, between 20 and 40 people come by on a visit day or in between to get an impression. Those who apply with a complete dossier are invited to a two-day aptitude test. We fill two to three places there each year. We currently have a total of ten apprentices. We remain small and are geared towards the size of Switzerland, although it is also easy to find a job abroad in this profession."

-

Stefanie Munz, a future organ builder in her 4th year of training, cuts leather on a glass plate, which she later glues together with the matching wooden construction to form a bellows.

The five other professions are learned in a training company, as is customary in the Swiss dual vocational training system, and attend trade school and various subject-specific inter-company courses. For apprentices from all over Switzerland, these take place at the Arenenberg Education and Advisory Center on Lake Constance. They attend the vocational school there for around 9 weeks a year in bilingual block courses. There are currently 41 young people, spread over 4 years of training and 5 specializations. This corresponds to the average of the last 10 years since these professions merged to form a joint training program, with around 80 % of lessons being taught jointly in the first year of training and 20 % in the last, with the rest being subject-specific. Jörg Gobeli, former head of the musical instrument making department at Arenenberg, admits, however, that a few more interested students could not hurt, so that the training companies would have more choice. And there are still some apprenticeship vacancies.

-

Marius Aebi, a future 4th-year piano maker, checks the shape of the hammer heads after sanding them with sandpaper. Sanding makes the grooves left by the strings over time disappear.

"There's plenty of work," confirms Oliver Zanella, who trained in both organ and piano making and has just started his own business. "Trained musical instrument makers have no problem finding a job, because there will be a kind of generational change in the next few years. The training you receive here is also highly respected worldwide and you have good opportunities to work abroad." The four-year apprenticeship in Switzerland is unparalleled internationally. In most countries there is no regulated training at all, but even in Germany the apprenticeship only lasts three and a half years. It is more difficult to find a training company, at least in the desired region. But that remains the first step. Zanella also strongly recommends getting a taste of potential training companies.

The musical instrument makers' interest group IGMIB provides information for prospective apprentices and maintains a list of companies that have already trained apprentices.

- Anika Batt, future violin maker in her 3rd year of apprenticeship, pricks the scroll of a viola. Jana Zurkinden, future 4th-year wind instrument repairer, removes a worn pad from a saxophone key and replaces it with a new one. Corina Baumann, future violin maker in her 3rd year of training, planes the arching of a soundboard.